The CAB-2 Vertical Control is designed specifically for controlling and enhancing the performance of Pines 3T, 5T, 14T, and other vertical benders.

A perfect replacement for all versions of the Pines Dial-A-Bend vertical tube bender.

Manual angle stops are eliminated, and bend angle adjustment is no longer a matter of time-consuming trial and error.

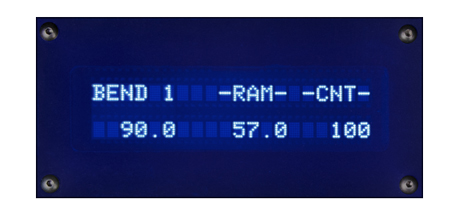

The operator no longer needs to keep track of and rotate the manual angle stops to match the next bend angle. Control-A-Bend vertical tube bender control automatically advances the bend number and updates the display.

Bend angles can be programmed to .1 of a degree. A high resolution optical encoder is used to feedback bend angle degrees to the control.

Since bend angle adjustment is no longer a matter of trial and error, your material scrap rate will decrease significantly. The Springback test routine and calculator can also be used to reduce scrap.

Control-A-Bend uses only the highest quality components to help ensure maximum reliability.

Plain language menus allow for quick and easy operation. No numeric codes are required.

Heavy-duty pushbutton switches are used for recurrent operations instead of membrane switches or cheap touch screens that are prone to early failure.

Optically isolated I/O modules provide high noise immunity while increasing reliability and bender up time.

Heavy-duty, industrial, oil resistant, high resolution encoder is used to provide optimum performance and repeatability.

Differential line driver interface for encoder is built into the controller to provide optimum noise isolation.

The CAB-2 Vertical attaches to your bender’s electrical box using a heavy-duty quick disconnect. Screw terminals are used to easily wire the bender’s solenoids and sensors.

Replaced Dial-A-Bend

Supports Light Curtains, Laser Scanners, and Safety Mats

No, our control can be installed onsite at your location. This will save you money on trucking costs and also reduce the amount of time your bender is down.

Yes, many of our customers install the control themselves. We have a comprehensive installation guide and we are also happy to provide remote assistance if needed.

Yes. In some cases our customers are too busy or not comfortable installing the control themselves.

We can normally install and test it within 2 days.

CAB-2 Vertical was designed to work on all models of Pines vertical press benders.

Customers like our CAB-2 Vertical because it is so simple to use, reliable, and well supported. In addition, we use heavy duty push button operator switches instead of custom membrane pads that need to be replaced often.

You will have unlimited phone and internet support from experienced engineers in our offices in Denver, Nashville, and the UK.

Since 1988. With over 1800 tube bender controls in the field, we are here to stay.